User Supplied Equipment

On this page: Scientific Equipment Interfaces | Spares | T-handles | Weight and Buoyancy |

Scientific sampling with Alvin can range from relatively simple procedures like rock retrieval to more complex data collection using specialized sensors. The submersible's capability to interface with instruments, and the reduction in size of many external sensors, has enabled acquisition of a wide range of data types and greatly improved the quality and quantity of the data collected.

Although many of the sampling techniques used during dives have been developed and refined through years of practice, Alvin Group engineers are available to assist with the development of mission-specific sampling concepts. This may include discussion of in situ experimental methods and sampling techniques, design of custom sensors, joint operations with other vehicles (e.g., AUV Sentry), use of sampling elevators, etc.

The following are brief descriptions of the sampling gear routinely available for use by cruise participants. In most cases the samplers are resident on the support ship and available on short notice. In a few special cases there may be some lead time associated with preparation and availability of the equipment. In all cases the requirements to use Alvin-supplied sampling equipment must be made known to the Alvin Group as far in advance as possible during pre-cruise planning.

Pressure Housings

All instrument or other water-tight housings taken to depth are considered potential implodable volumes, and as such must be certified for use on Alvin. Implodable volumes are any pressure housing with a non-compensated compressible internal gas volume at a pressure that is either above or below the external ambient sea pressure with a potential to burst or collapse.

Read more

Housing assemblies must have unique permanent identification numbers. If permanent marking is not possible a tamper-proof label shall be applied. Test documentation must reference all identification numbers. Implodable volumes must have the certification depth clearly indicated on the exterior of the housing.

Implodable volumes shall be pressure tested to 1.5 x maximum external operating pressure. Maximum external operating pressure is the ambient pressure at the maximum depth at which the item or component will be operated. Hydrostatic pressure at 6,500 meters of seawater is 9,679 psi. For the purposes of testing, use a conversion factor of 1.489 psi/meter to calculate hydrostatic pressure at depth.

Certification of an implodable volume requires an external hydrostatic pressure test to 1.5 x housing certification depth (meters) x 1.489 psi/m, +300/-0 psi. Housing certification depth is the maximum depth at which the implodable volume is authorized for use on Alvin. Each test requires a minimum of 10 pressure cycles as follows: 9 cycles held at maximum pressure for 10 minutes, followed by a single cycle held at maximum pressure for 1 hour.

Leakage or visible signs of external damage shall be cause for test failure. Where several housings of a particular type are to be utilized, each housing shall be pressure tested; i.e., representative testing of one vessel in a series will not be accepted.

Although pressure test certification for Alvin purposes does not expire, consideration should be given to retesting every five years. The Expedition Leader may refuse to honor a valid certification if the condition of the housing has deteriorated since its last pressure test. Modifications to the housing such as machining, drilling, connector replacement, etc., void pressure certification and thus the vessel must be retested after any work that could compromise structural integrity.

The test chamber pressure recording chart (or copy) and/or statement of test details signed by the chamber operator shall be delivered to the Alvin office at Woods Hole, and a copy shall be delivered to the Expedition Leader aboard Atlantis prior to ship departure and subsequent equipment installation on Alvin. Follow the link in this section to obtain an Alvin hydrostatic pressure test record form.

Pressure vessels constructed from certain experimental or unpredictable materials such as glass or ceramics cannot be certified for use with Alvin in the manner described above. In some cases, a design review by Alvin’s U.S. Navy engineering oversight body (NAVSEA) is required (a time-consuming process) and in others, certification is impossible. If in doubt about a particular design, contact the Alvin office.

Certification documentation for valid pressure tests require very specific information so if any questions exist, users are encouraged to contact the Alvin Group for clarification of these requirements. Prior to an expedition, users are encouraged to provide copies of pressure certification documentation to the Alvin Group for review. Users are also required to provide hard copies of pressure certificates to the Expedition Leader for our Certification files. This documentation must be complete and should be inclusive of all items to be deployed or recovered by Alvin. These documents will not be returned and will be archived and audited as objective quality evidence for sustaining the vehicle’s Navy certification. These files are not archived locally on the ship and must be provided prior to each expedition that a given piece of equipment is used with the vehicle.

Off- Gas Testing of Equipment to be Used in Alvin's Personnel Sphere

The U.S. Naval Sea Systems Command (NAVSEA), Alvin's certifying agency, requires toxicity and flammability testing of all scientific instrumentation brought into the personnel sphere. The testing consists of a 24-hour, power-on bench segment to record maximum component temperatures, followed by 24 hours in an isolated chamber at 100degF to measure offgassing. The tests are performed at WHOI and at a lab in Connecticut at least once per year and are announced 30 days in advance. Items are tagged following testing, and a list of tested material is maintained at WHOI so that repeated tests of unmodified instruments will not be required.

Remember: if your gear is not tested, the Operations Group on board Atlantis will not allow it to be taken into the sphere. Any questions about this procedure should be directed to Rick Chandler at WHOI.

Weight and Buoyancy

The Alvin Group calculates the submersible's payload as a part of the preparation for every dive. Air and water weights of installed user-supplied equipment and sampling tools are included in these calculations. It is important that accurate air and water (buoyancy) measurements are obtained for all science-supplied items intended for use on Alvin and/or deployed platforms (elevators). The Alvin Expedition Leader will request the air and water weights for all science gear at the beginning of each cruise.

Read more

Although use of a model to calculate air weight and net buoyancy of an assembly is possible, it is much more accurate to obtain air and water weights via empirical means. Air weights may be found via standard means (appropriately sized scale). Buoyancy measurements require that the item be submerged in sea water while measuring the resulting weight or buoyancy of the item. Although not typical, users should be aware that some items may be neutrally or positively buoyant in sea water which could have an impact on use during sampling. These items may be prone to float from the basket and thus require additional consideration.

Obtain weight and buoyancy for fully assembled components where possible and fully submerge the items during measurements. To ensure accuracy during measurements, it is important to ensure all equipment air voids and cavities are fully flooded to the extent possible. For larger items, obtaining buoyancy may require the use of a crane and load cell to fully submerge the item in sea water. With prior planning assistance may be available as a part of cruise mobilization (typically the two days prior to departure from port).

The Alvin Group can provide additional guidance and assistance as required.

Glass Flotation Spheres

Glass flotation spheres deserve special mention because of their common usage. These implodable volumes cannot be certified by pressure testing because of their susceptibility to failure as a result of minor damage. As a consequence, Alvin will handle instruments utilizing these spheres in only three ways:

Read more

- An instrument using glass spheres for flotation will be carried to or from the bottom by Alvin provided the spheres are tethered above the instrument at a distance of at least 100 meters.

- Alvin will move an instrument on the bottom (including limited vertical excursions) provided the flotation spheres are tethered at least 30 meters above the instrument.

- Alvin will approach a glass sphere on the bottom to within photographic range but will not touch it. The only exception here is the case where Alvin approaches to grasp a trigger or release lanyard which is long enough to allow the submersible to back away a suitable distance before activation.

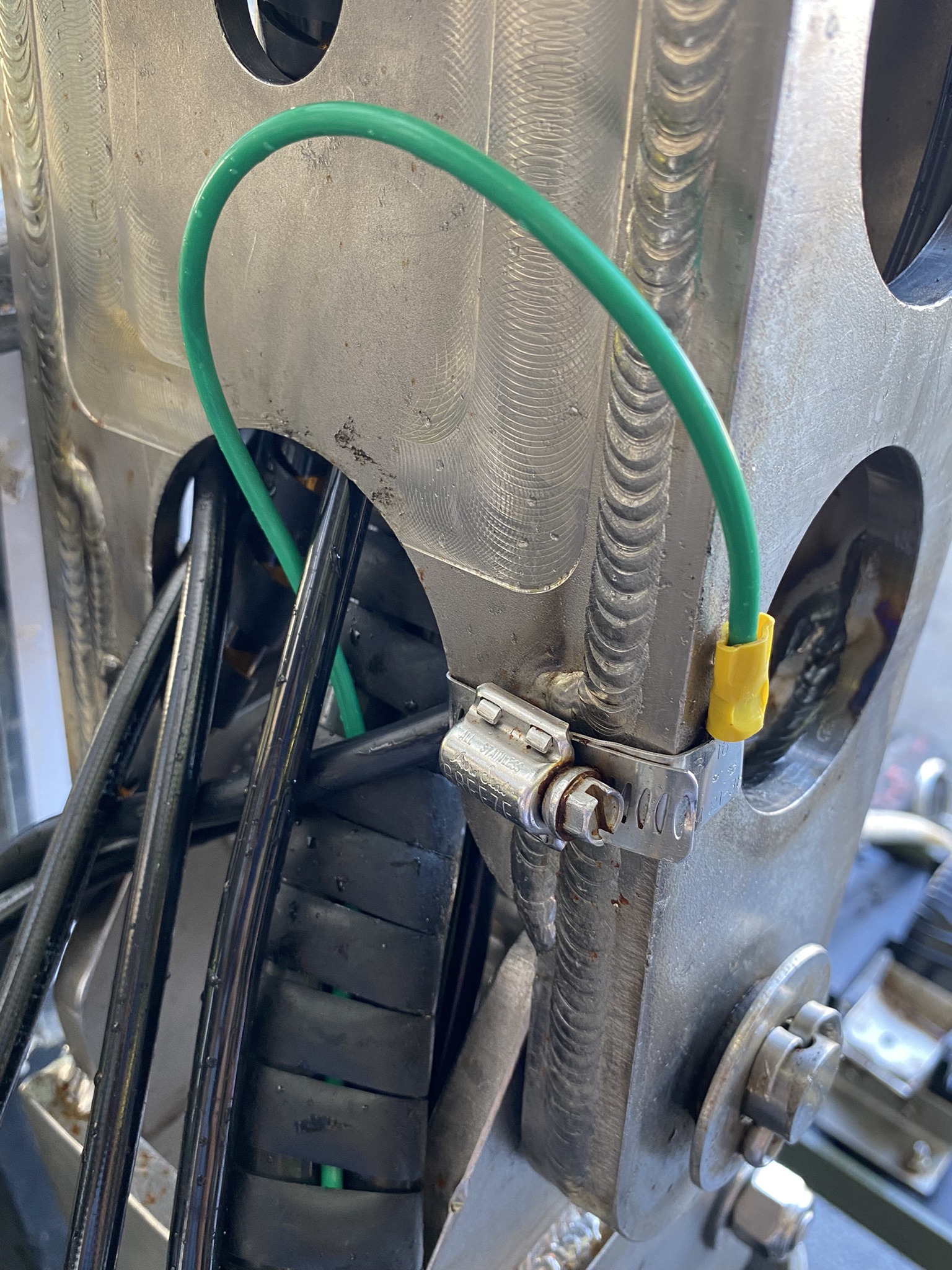

Ground Monitoring

All of Alvin's electrical systems and through-hull wiring must be UNGROUNDED to limit the chance for corrosion of structural parts in the event of inadvertent grounding of any conductor. Alvin's electrical systems are frequently checked for grounds during each dive. There are four requirements that each science device must meet:

Read more

- No device may permit, or cause, a direct DC path between any source of Alvin power and the submarine's hull, frame or seawater.

- No device connected to through-hull wires may permit any DC path between any through-hull wire and the submarine's hull, frame or seawater.

- All devices connected to through-hull wires must provide a DC path from an Alvin power source to all such through-hull wires so that the submarine's ground detection system can be used to check for inadvertent grounding of through-hull wires. The easiest way to provide this connection is with a resistance of from 0 to 3 Kohms between the instrument's internal ground and the input power common.

- Isolated or battery-powered equipment may be used, though it must still adhere to these requirements. In some cases an independent ground detector must be fitted to the circuit.

NOTE: if grounds are detected on any through-hull conductors, the source of that ground must be identified and that system must be secured for the remainder of the dive. A grounded device will not be allowed back on the submersible until the source of the ground is identified and removed.

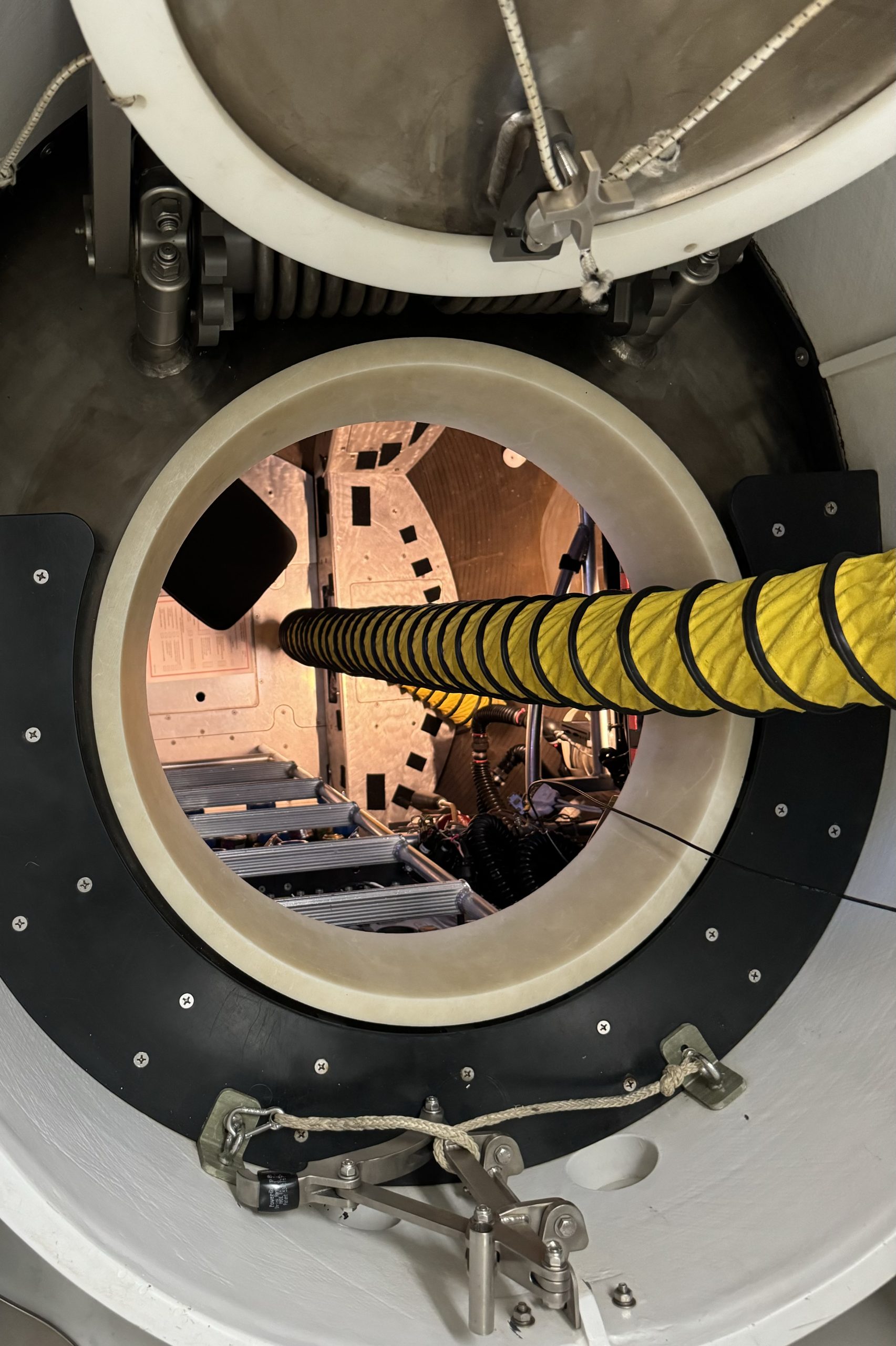

Hatch Size

The hatch opening is 20 inches in diameter. Any equipment which users wish to bring on board must be capable of passing through the hatch with its sealing surface protection ring in place, resulting in a working 19” maximum opening.

Spares

Many user-supplied sampling devices, cameras and sensors are unique, are likely very specialized, and as such may have a higher incidence of problems during a dive series. The Alvin Group strongly recommends that when a science program includes a user-supplied, specialized tool, camera, or sampling device, that sufficient spares are available for use in the event of a problem. Examples include spare cabling, o-rings and/or seals, tubing and fittings, valves, power supplies, data interfaces (Moxas) and other critical items that may experience problems or failure during a series.

Read more

A general rule of thumb is to expect some form of minor equipment issue, and to arrive prepared to respond to the problem with a reasonable complement of sparing and tools.

The Alvin Group will provide as much expertise and problem evaluation as possible, and where possible and practical, the Group may be able to provide basic equipment support. But for unique sampling devices it is imperative that critical spares are available.

Additionally, the Group recommends that cruise participants bring sufficient 'dummy' plugs and caps, capable of protecting sensitive electronic connectors and plugs at depth.

Users should also ensure that they are well equipped with any specialized or unique tools and hardware that are important for the preparation, mounting or support of their equipment.

The Alvin Group can provide guidance for spares and tooling as part of the pre-cruise planning process.

Scientific Equipment Interface

The design of the Alvin electrical system includes the capability to interface to a wide variety of science equipment. In general, though Alvin personnel will do their best to perform the final installation of the equipment onto the submersible, the specific condition or configuration of the vehicle may make one or more of these capabilities unavailable. To make this go as smoothly as possible, proper planning, testing and communication with the Alvin Group is recommended (also see Pressure Testing for User-Supplied Equipment). When delivering equipment to the Alvin Group, it is important to provide adequate documentation, including schematics, wire colors, connector types, and test documents (where necessary).

The available volume for additional in-hull equipment is very limited. In general, only small hand‑held equipment should be considered for in-hull use. It is best for these to include a connector for their interface cable, so they can be disconnected for storage.

Electrical

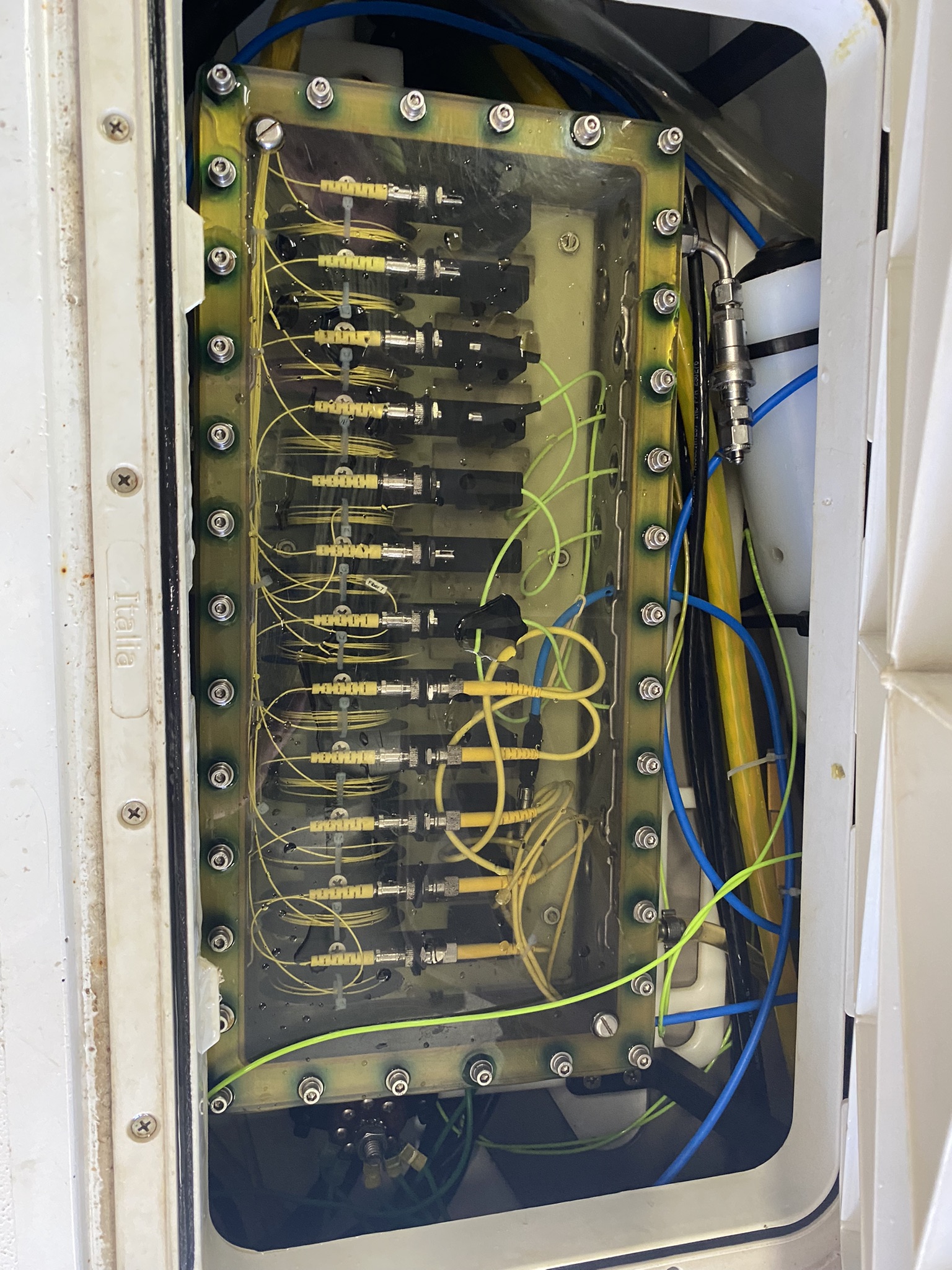

There are a total of 46 through-hull wires available for science equipment use. These are all 16ga, fused at 10A (fast), and some are in twisted pairs. Because of wiring constraints, circuits using these conductors must be able to tolerate up to 1 ohm of end-to-end resistance on each wire. These wires are terminated in-hull in AMP 206838-1 circular plastic connectors (CPCs); the mating connector for this is AMP 206837-1. Outside, these terminate in one of the Science Basket J-boxes.

T-handles

The jaws of both manipulators are functionally equivalent and consist of opposing overlapping finger pairs. They are specifically designed to grip instruments which are fitted with a standard "T"-handle. The user should align the "T" with the vertical load. The user is cautioned not to assume compatibility between your tools and Alvin's manipulators, even if the tools are fitted with T-handles. It is best to seek the advice of the Alvin Group on instruments which have not been previously used with the manipulators, regardless of how dependable they may seem. Many biologically and geologically oriented tools, including a variety of pry bars and other rock breaking tools, soft and hard sediment corers, box corers, and current meters have been adapted for use in conjunction with the manipulator jaws and the associated actuator mechanism.

Power

There are six power channels available for outside science equipment use. Each of these is 24V at up to 150W, though full power may not be available from them all at once. Power channels terminate in one of the Science Basket J-boxes, and are controllable through the in-hull GUI controls.

Read more

A high-power channel is also available that can provide 120V at up to 10A. Specific arrangements must be made before planning to use this power channel.

Additional power channels may be available for in-hull science equipment use, provided through the Data Power Controller. Voltages of 5V, 12V or 24V may be available, depending on other submersible equipment requirements.

Data System and Acquisition

The Alvin data system consists of sensors, a data transport layer and data acquisition/storage in the form of in-hull computers. The majority of the sensors are permanently installed, including depth, altitude, CTD, etc., and are serial devices that use a serial to Ethernet bridge (Moxa) to transport data in-hull. Science wires are available and assigned as needed on a cruise-by-cruise basis if this architecture is not appropriate for your application. Data can be sent to any address on the network for logging and/or processing. The in-hull network can be accessed using the installed Alvin computers or via science-provided equipment.

Read more

There are four through-hull serial data channels available for external science equipment interfacing. Each of these channels is full‑duplex RS232, up to 115 Kbaud. Outside the hull these channels are accessible in one of two Science Basket J-boxes. Inside the hull these channels are terminated in a DB-9S connector. They can also be made available on the submersible's network using a Moxa device.

Data may be accessed in-hull via the submersible's network, using wired and wireless connections via a UDP transport layer, or it can be converted back to RS232 serial data. USB to serial adapters are available for use with laptops that lack RS232. If science wires are used, those connections are made available inside the sub through the Science Panel interface.

There are several options for computing in-hull. First, there is a dedicated science computer running Windows 7 or Linux in a dual-boot configuration. This computer has Alvin network access and has limited peripherals available (one USB and one serial port). Alternately, the Alvin group can supply a toxicity/flammability-tested Windows laptop.

If these options are not acceptable scientists may supply their own device, though this requires pre-cruise toxicity and flammability testing. In these cases please contact the Alvin Group as early as possible to review and schedule the testing procedure.

Additionally, there are also two Ethernet data lines available for outside science equipment integration. Though these provide 100Base-T signaling, experience has shown they may actually provide significantly less data throughput. Outside the hull, these Ethernet lines are accessible in one of the two Science Basket J-boxes. Inside the hull, these lines are terminated in RJ-45 connectors.

Optical Fibers

Two optical fibers (SMF-28 or equivalent, Single-Mode, 9/125 micron) are available for science equipment use. These are terminated in ST inside the hull and in the optical junction boxes. Though virtually any wavelength may be used, for compatibility it is recommended to have the in-hull equipment transmitting at 1310nm and the outside equipment transmitting at 1550nm.

Real-Time Processing

In-hull computing resources are available to minimize the need for separate scientific computers. Access to a computer (either installed or tablet) can be made available to run science equipment applications. In general, these machines have modest computing capability, USB ports, and are on the submersible's network. They are satisfactory for data logging and instrument control applications, though computationally-intensive functions should be saved for post-dive processing.

Video

The Alvin video system can handle multiple inputs of varying formats. In addition to the standard compliment of imagers, the system is flexible enough to allow the user to integrate custom-designed and commercially available video and still cameras both inside and outside the personnel sphere.

Inside Cameras

The Alvin Group provides an in-hull, hand-held still/video camera. Additionally, the Group also maintains a supply of GoPro cameras that can be provided upon request.

If the user would like to provide their own in-hull camera, it is recommended that it be battery powered and internally recording. If the camera provides a a video output it may be able to be integrated into the vehicle's video system for display and recording. Prior arrangements must be made to ensure compatibility of this signal with the submersible's video system. User supplied in-hull cameras can be used but must be cleared with the Alvin Operations Group and must pass toxicity and flammability testing protocol.

Hydraulic

Hydraulic systems can be an efficient method of supplying large amounts of mechanical force almost instantaneously. Hydraulic systems are also robust and reliable. Alvin utilizes hydraulics for several functions.

Read more

Alvin's hydraulic system is designed to supply hydraulic power for both submarine-specific functions and science applications. The system is used to power the manipulator arms, trim adjustment, and variable ballast control. The hydraulic system can also power any science gear that uses hydraulics. Power is generated by two 6HP hydraulic power units. The Pilot distributes power via electronically-controlled valves.

Four independent hydraulic control valves are available for science use. They are all directional proportional valves which can supply up to 2GPM at 1800 PSI. All science circuits have 2500 PSI relief pressure. These relief valves provide load locking to the limit of the relief.

When the manipulator arm is activated, oil flow priority is given to the manipulator. The port arm requires up to 3 gpm and can use all the available flow for short periods of time. This can cause interruptions and/or reductions of performance in other hydraulic functions that are operating. If uninterrupted use of science hydraulic operations is required, the manipulator arm should not be used when the science hydraulic system is on.

The Alvin system uses Royal Purple Marine Hydraulic Oil. High pressure 10 micron and water removal filtration is provided.

Note: Despite taking many precautions, the Alvin hydraulic system should not be considered "clean". Science equipment must be robust enough to operate with potentially contaminated oil.

Alvin uses flexible hydraulic supply hoses which are connected to hydraulic manifolds with 1/4" Swagelok fittings. Hoses used to supply equipment mounted on the science basket must pass through a disconnect plate to allow emergency release of the basket.

For the latest information on the hydraulic system, please contact the Alvin Group in advance of intended use of the science hydraulic system.

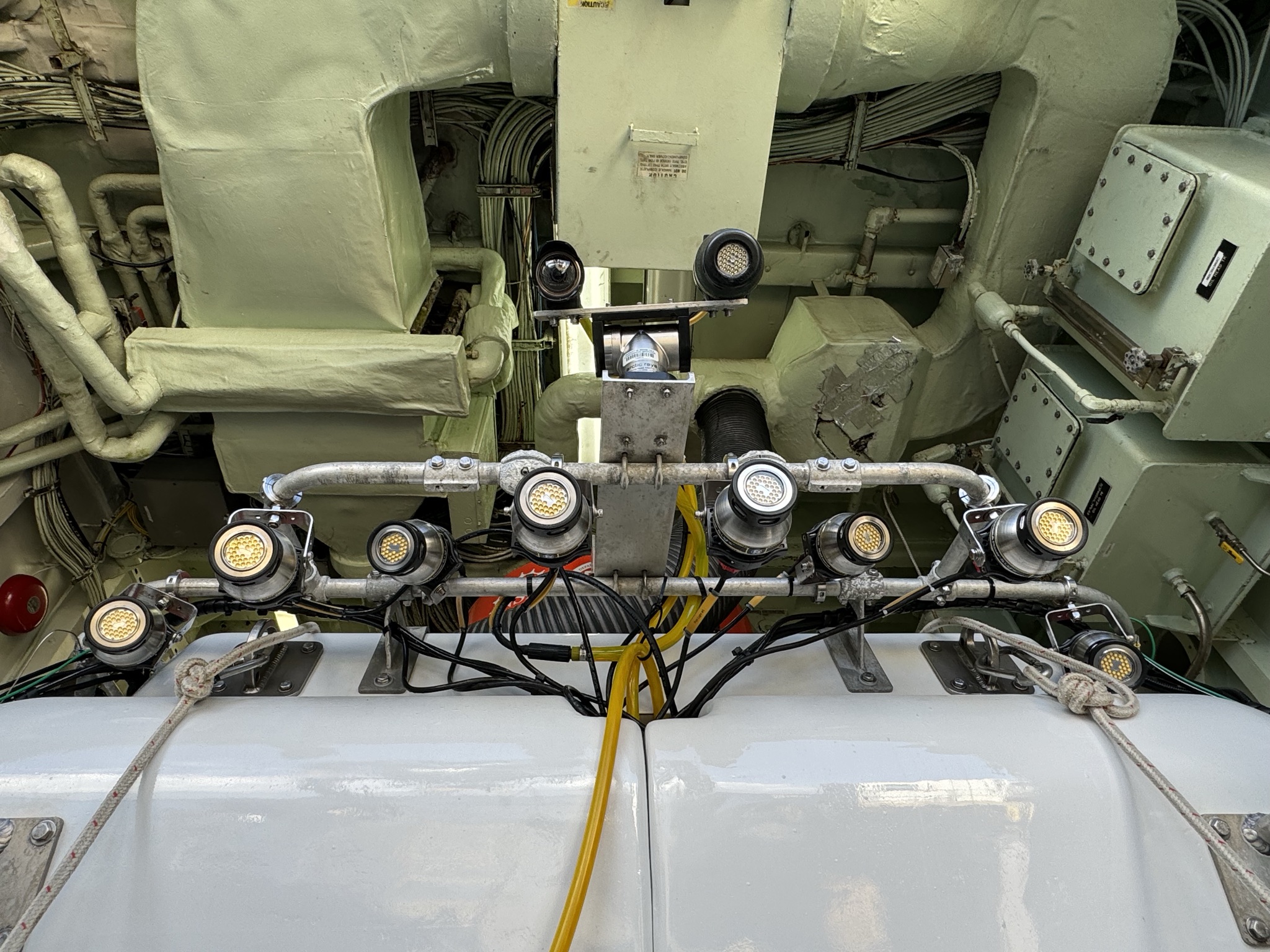

Light Bar

The light bar is a 1-inch aluminum tube structure located on the brow of the sub. Alvin lights and cameras are mounted to the bar but there is also limited space available for mounting science equipment. Equipment mounted on the light bar must have relatively low mass due to mounting constraints and to minimize effect on stability. The light bar is best for small instruments which need to be higher up on the front of the sub. If space in the light bar is required, the user should contact the Alvin Group for specifics on mounting requirements. The science user must supply the proper mount to attach the gear securely.